Household appliance molds are an essential part of the production process for plastic household products, including components for washing machines, refrigerators, and other appliances.

The use of household appliance molds enables faster and more efficient production of household products, while reducing manufacturing costs and improving product quality. This is particularly important for companies involved in the production of household appliances, as the market demands high-quality products at reasonable prices and with fast production times.

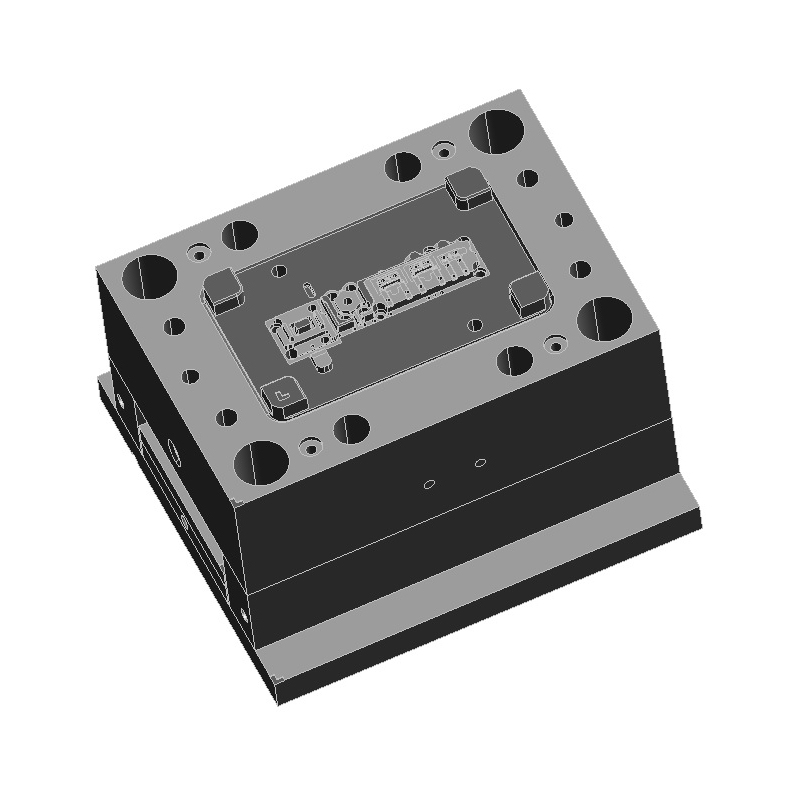

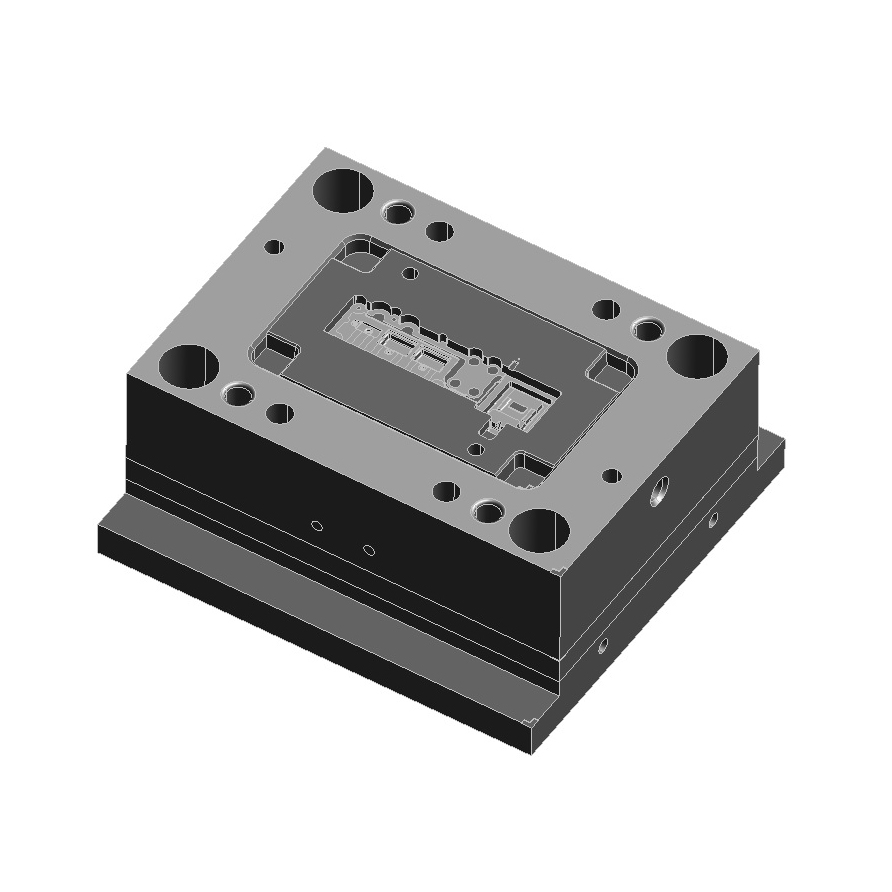

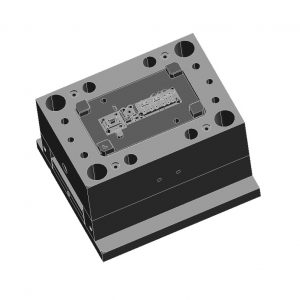

The process of manufacturing household appliance molds typically involves the following steps. Firstly, the mold design is created based on customer requirements or existing product samples. Then, the mold is fabricated using CNC machining or traditional manual methods. Once the mold is completed, manufacturers use it to inject plastic into the mold cavities to produce the desired household product components. Finally, the components are finished and assembled to create the final household appliance.

In summary, household appliance molds are a crucial manufacturing technology in the household appliance industry. They help improve product quality, reduce production costs and time, and meet the increasing market demand for high-quality and reasonably priced household products.