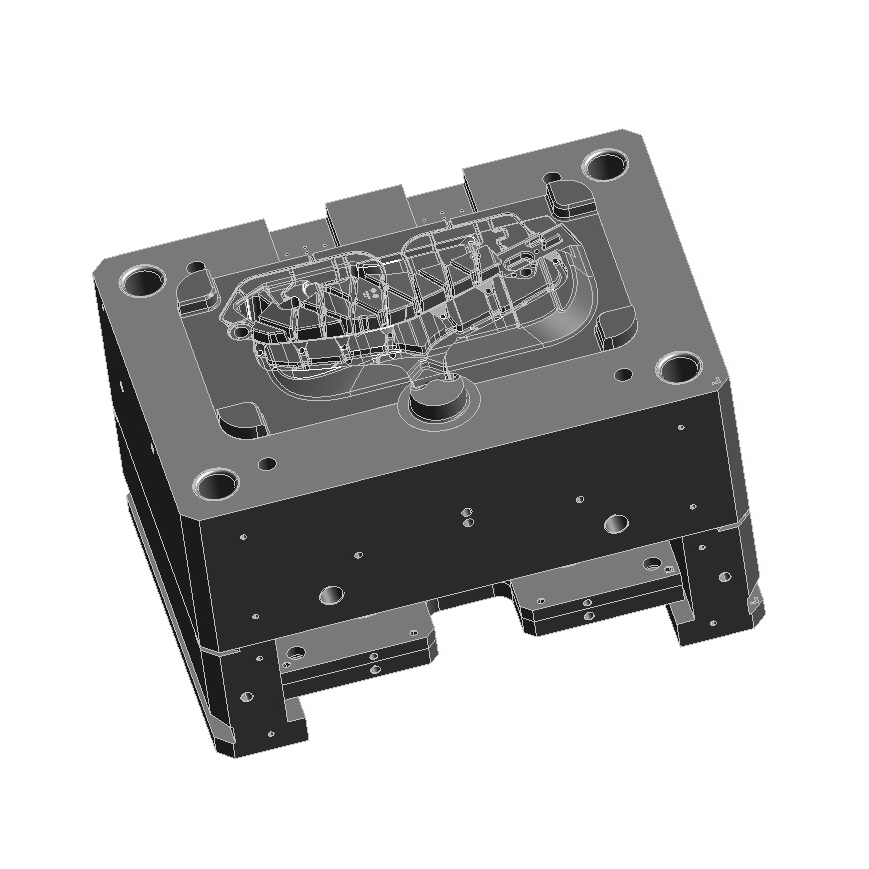

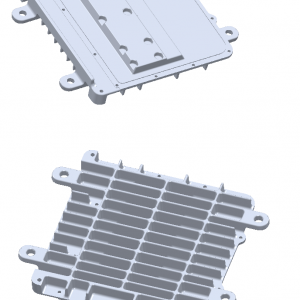

High-pressure die casting mold 3

Aluminum material: ADC12

Shrinkage: 6/1000

Product dimensions: 647x189x189

Core, cavity material: DHA-W

Number of mold cavities: 1

Mold base material: S50C

Mold dimensions: 760x1080x850

Casting machine: 800T

Production output: 100k

Application: Motorcycle parts

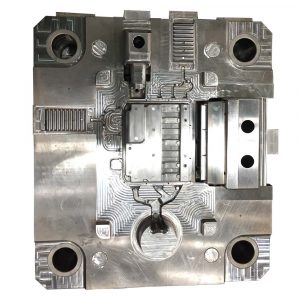

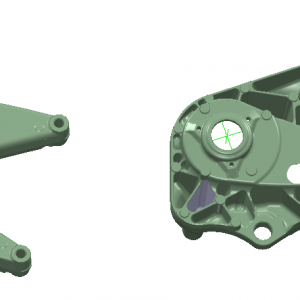

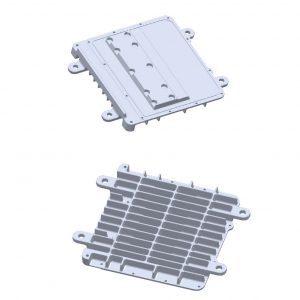

High-pressure aluminum die casting is a precision casting technology that utilizes metal molds to produce high-precision aluminum parts. High-pressure aluminum die casting molds are used to manufacture aluminum parts for motorcycles, including motorcycle body panels.

The use of high-pressure aluminum in the production of motorcycle parts is due to its higher strength and hardness compared to conventional aluminum, especially under high loads and vibrations. This improves the performance and longevity of aluminum parts on motorcycles.

High-pressure aluminum die casting molds for motorcycles are typically designed and manufactured by professional mold suppliers. The process of producing high-pressure aluminum die casting molds for motorcycles includes mold design, mold machining, and mold testing to ensure the quality and accuracy of the die-cast aluminum parts. Once the molds are produced, they are used to cast motorcycle body panels during the production process.