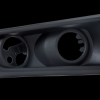

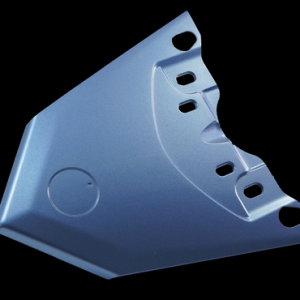

The plastic mold for the automotive component Air Outlet Grille

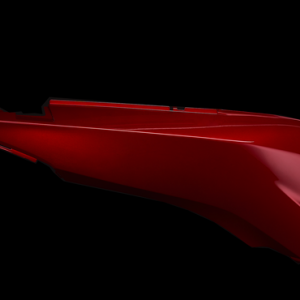

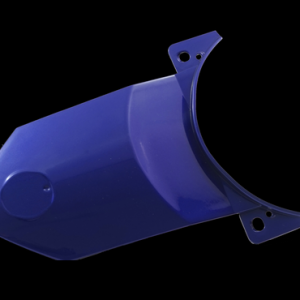

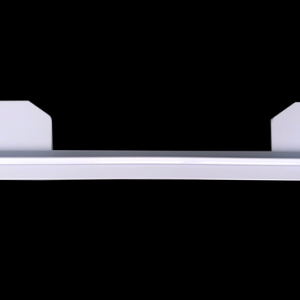

The plastic mold for automotive components is used to produce plastic parts for automobiles. Similar to automotive plastic injection molds, the automotive component plastic mold is made of steel or aluminum and designed with precise shapes and dimensions to create plastic components that fit accurately in automotive parts.

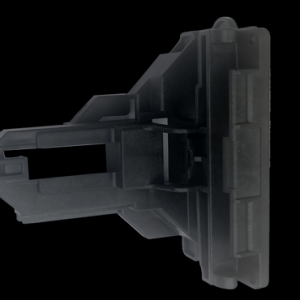

Plastic components used in automobiles include interior and exterior parts and accessories such as door handles, fuse boxes, air filters, car trunks, headlights, hoses, and more. The automotive component plastic mold plays a vital role in the production process of these plastic components, ensuring their quality and accuracy.

The process of manufacturing automotive component plastic molds involves various steps, from initial design to machining and finishing the mold. Subsequently, the plastic mold is used in the plastic injection molding process to produce specific plastic components. This process must ensure that the mold and injection molding process achieve high precision to produce plastic components that meet the exact size and shape requirements for automotive parts.