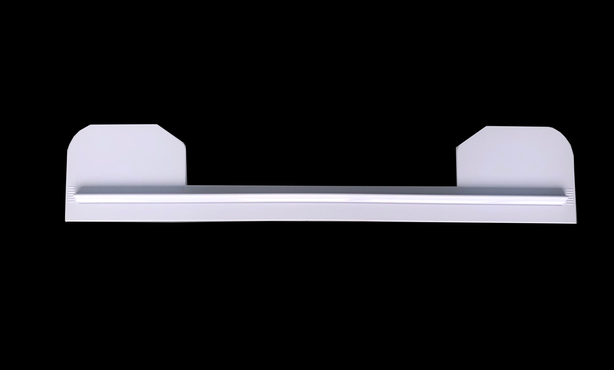

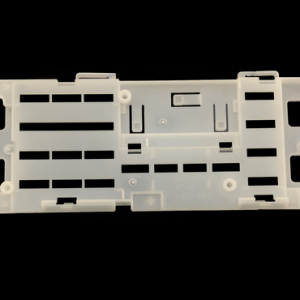

The washing machine Lid mold

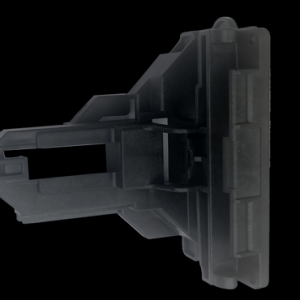

The washing machine plastic mold is a type of mold used to produce plastic components for washing machines. This mold is typically made of steel or aluminum and is designed with precise dimensions and shapes to create the exact size and shape of the components required for the washing machine.

The manufacturing process of the washing machine plastic mold begins with the initial design of the mold, followed by the machining of the mold to the required dimensions and shape. Once the mold is completed, it is used to mold the plastic components for the washing machine.

To mold the plastic components for the washing machine, the typical plastic molding process is employed, which includes the following steps:

- Preparation of plastic material: The plastic material is prepared and fed into the molding machine.

- Pre-processing: The plastic material undergoes pre-processing steps to ensure quality.

- Plastic molding: The plastic material is injected into the plastic mold to create the plastic components for the washing machine.

- Part ejection: After the plastic component is molded, it is ejected from the mold and cleaned.

- Finishing: The plastic component undergoes finishing processes such as trimming, grinding, or other steps to achieve the final required dimensions and shape.

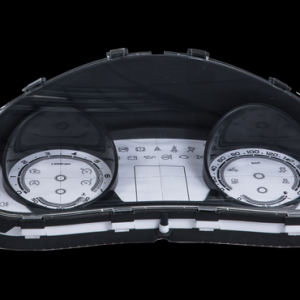

The washing machine plastic mold plays a crucial role in the production of plastic components for washing machines. It ensures the quality and accuracy of these components while ensuring that the washing machine operates correctly and meets the requirements of the users.