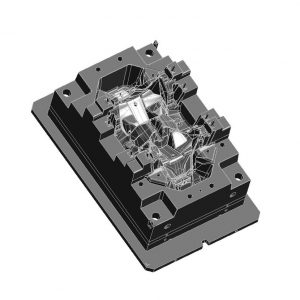

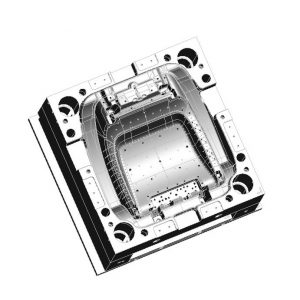

Motorcycle Component Mold 01

Plastic material: ABS

Shrinkage: 5/1000

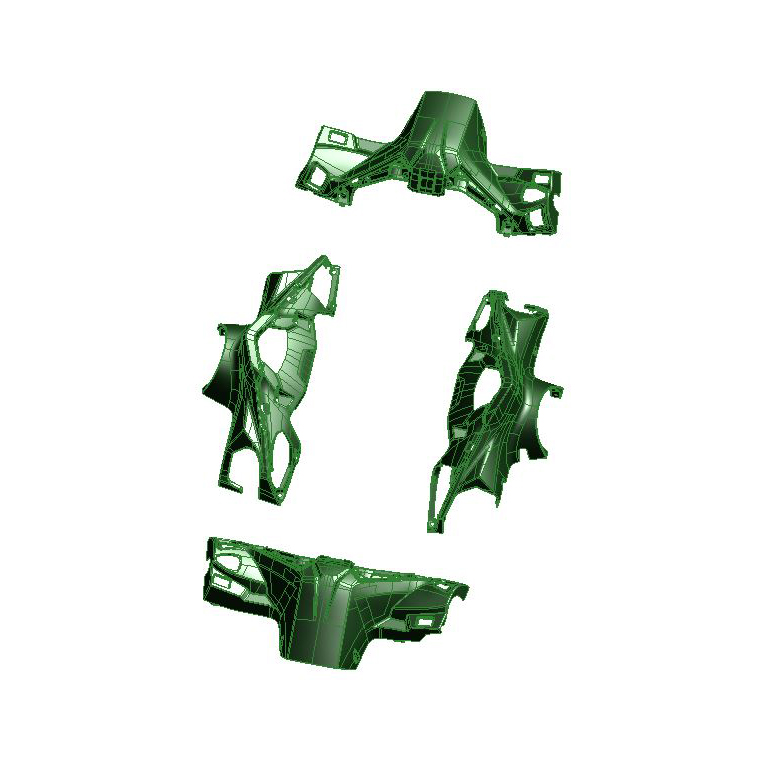

Product dimensions: 436.56X210.61X130.43;178.01X436.55X168.88

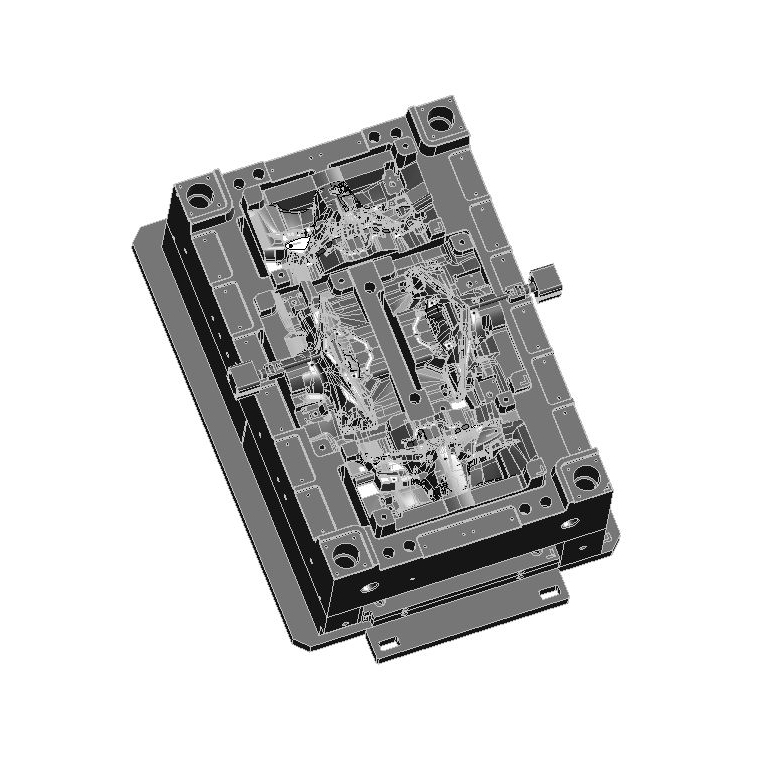

Core and cavity material: P20

Number of cavities: 4CAVITY

Mold base material: S50C

Mold dimensions: 1020x1400x890

Injection molding machine: 850/1050t

Production output: 300k

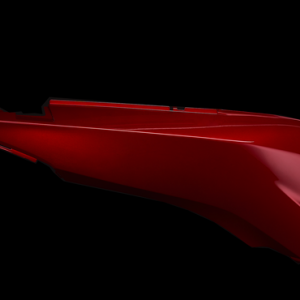

Application: Motorcycle components

Motorcycle component mold is a type of mold used to cast metal parts for motorcycles. These components can include engine parts, frame parts, body parts, electronic components, and other accessories.

The use of motorcycle component molds in manufacturing metal parts for motorcycles brings many benefits. Firstly, the casting process of motorcycle components using molds ensures accuracy and durability of the parts, thus improving the quality and reliability of motorcycles. Secondly, the use of component molds helps reduce production time and costs compared to other traditional manufacturing methods. Thirdly, component molds also contribute to waste reduction and material savings.

The process of manufacturing motorcycle component molds includes the following steps. First, the mold design is carried out based on customer requirements or existing part samples. Then, the mold is fabricated using CNC machining or traditional manual methods. Next, the mold undergoes testing and trial runs to ensure the quality and precision of the cast metal parts. Finally, the mold is used to cast the metal components for motorcycles.

In conclusion, motorcycle component molds are an important manufacturing technology in the motorcycle industry, enhancing the quality, accuracy, and durability of metal parts while reducing production costs and time.