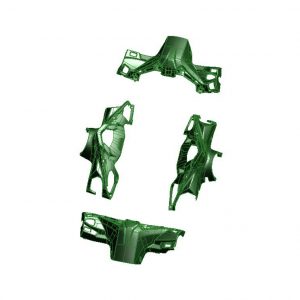

Plastic automotive mold 1

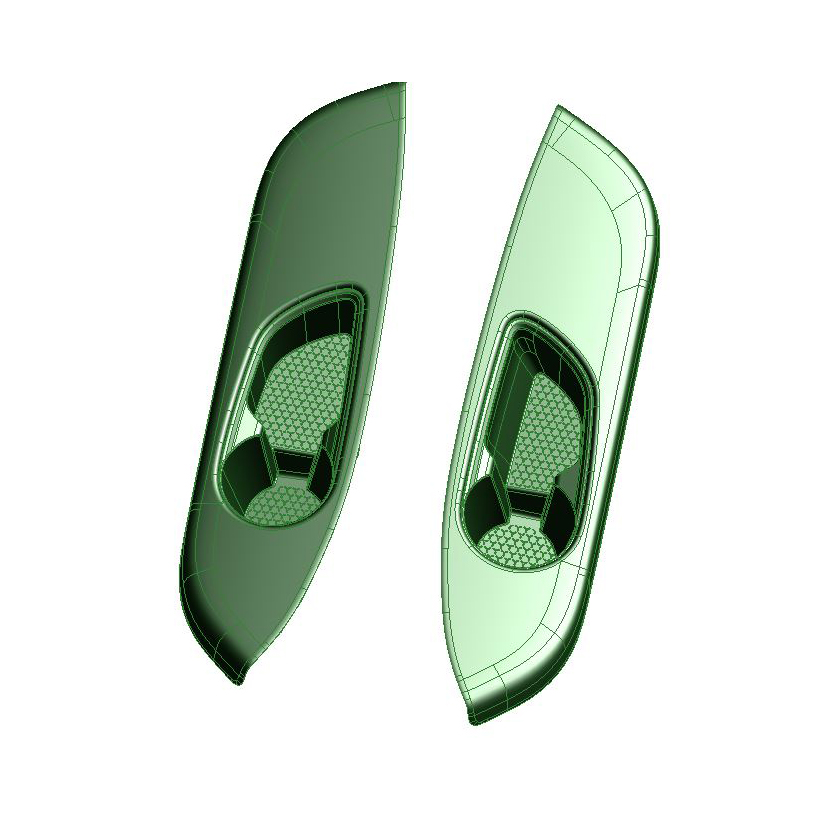

Plastic Material: PP-AS-005

Shrinkage: 15/1000

Product Dimensions: 526.16×125.34×129.45

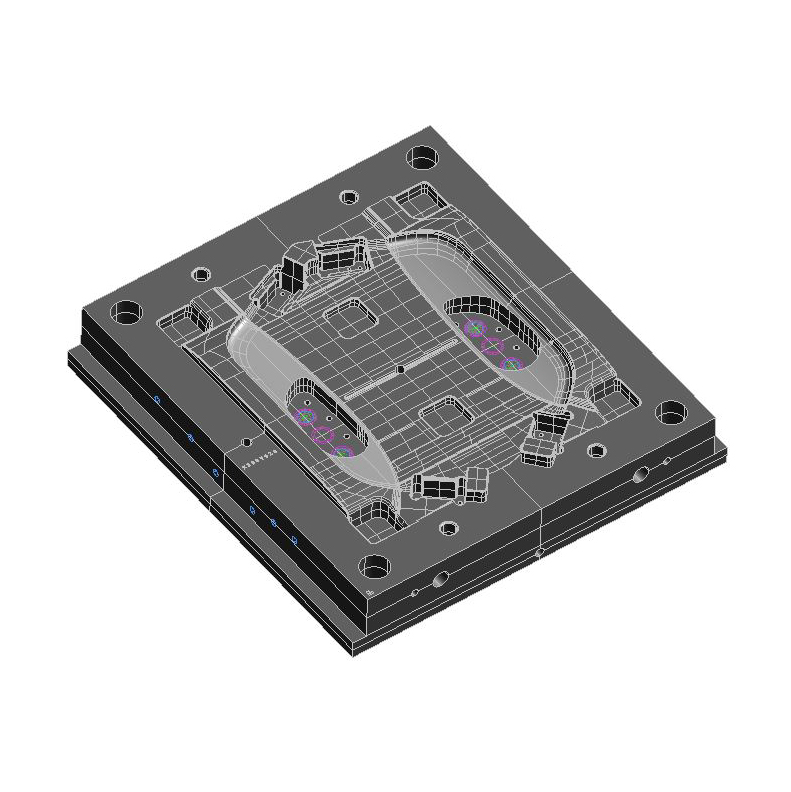

Core and Cavity Material: P20

Number of Cavities: RH/LH

Mold Base Material: S50C

Mold Dimensions: 900x900x565

Injection Machine: 550t

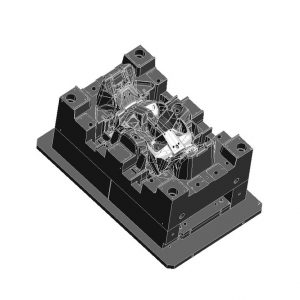

Production Volume: 1000k

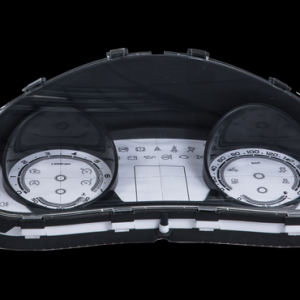

Application: Automotive Components

An automotive mold is a type of mold used to produce metal or plastic components for automobiles, such as car bodies, engine parts, interior fittings, and other components.

An automotive plastic mold is a tool used to manufacture plastic components in automobiles. Automotive plastic molds are typically made of steel or aluminum and designed with precise shapes and sizes to create accurately dimensioned plastic parts for various automotive components.

The process of manufacturing automotive plastic molds involves several different steps, from initial design to machining and finishing of the mold. Subsequently, the mold is used in the plastic injection process to produce specific plastic parts.

Plastic components used in automobiles include various interior and exterior parts and accessories, such as steering wheels, gearshifts, electrical distribution units, exhaust pipes, air ducts, headlights, fenders, windows, and much more. Automotive plastic molds play a crucial role in the production of these plastic components, ensuring their quality and precision.