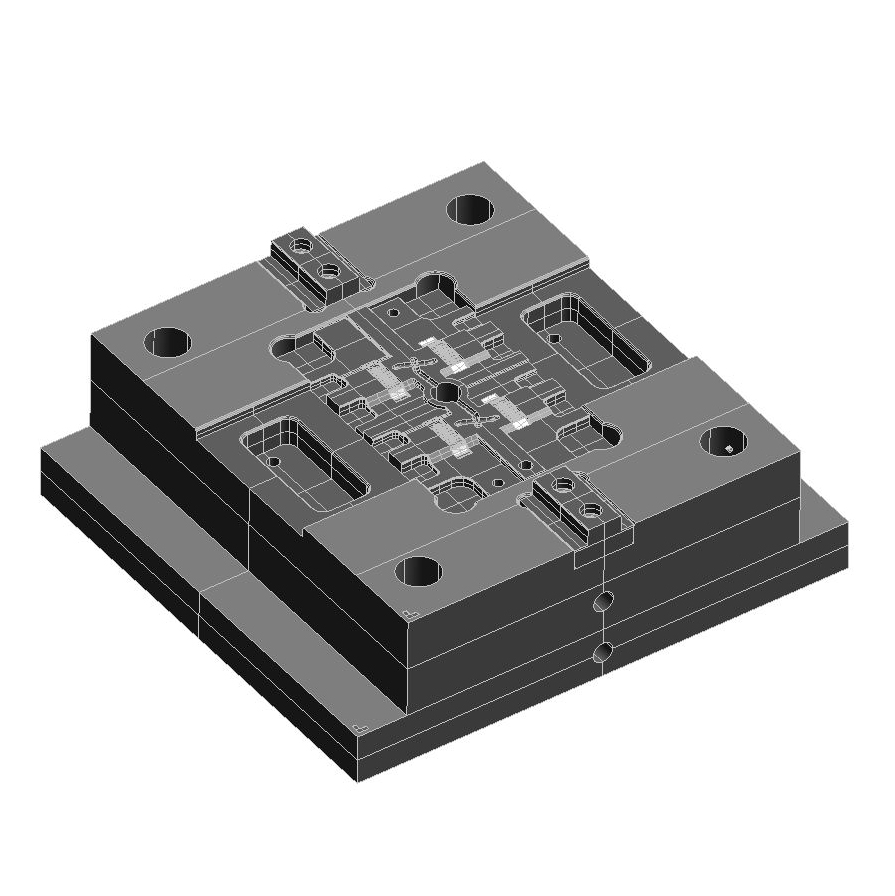

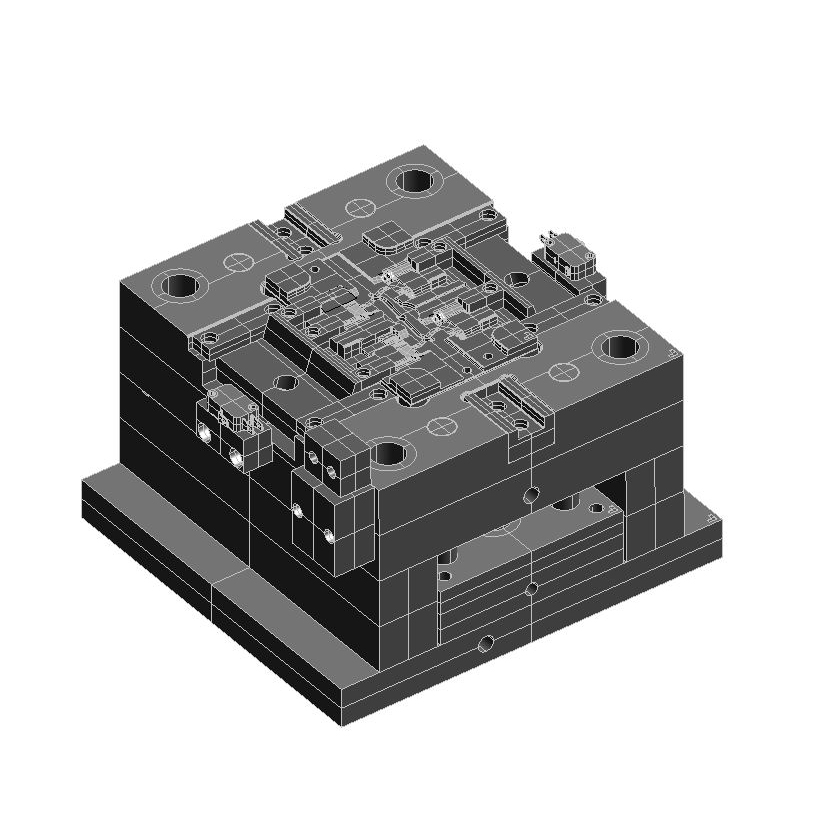

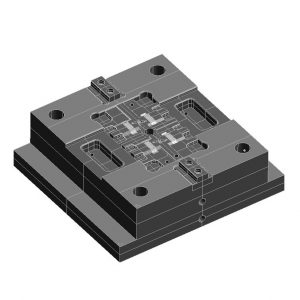

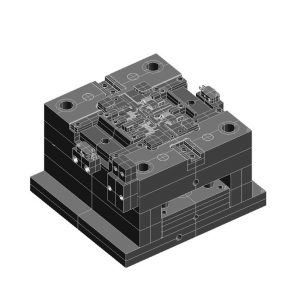

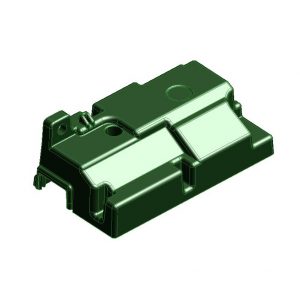

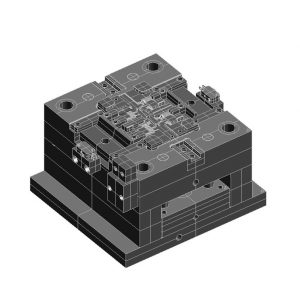

Plastic mold for printing machine 02

Plastic material: POM

Shrinkage: 20/1000

Product dimensions: 7.55 x 26.25 x 8.15

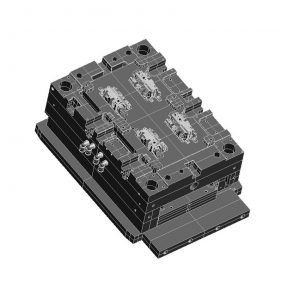

Mold dimensions: 250x230x220

Core, cavity material: S-STAR

Number of mold cavities: 4

Mold base material: S50C

Molding machine: 60T

Production volume: 1000K

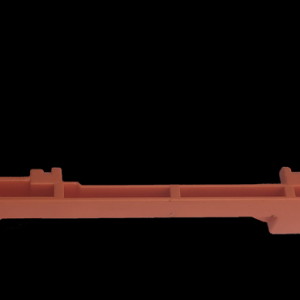

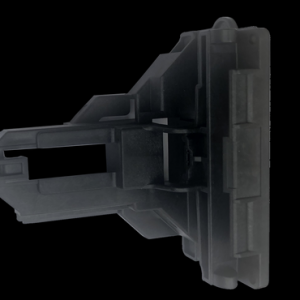

Application: Printer components

Plastic mold for printing machines is a type of mold used to produce plastic components for printers. These plastic components can include buttons, handles, printer casings, and other accessories.

The process of manufacturing a plastic mold for printing machines typically involves the following steps:

- Mold design: The first step is to design the mold according to customer requirements or based on existing plastic component samples.

- Mold fabrication: Once the design is completed, the mold is fabricated using CNC machining methods or traditional manual machining.

- Mold testing: The mold is tested and evaluated to ensure the quality and accuracy of the plastic components produced from it.

- Plastic component molding: After the mold has been tested and approved, it is used to mold the plastic components for the printing machine.

Using a plastic mold for printing machines in the production of plastic components for printers offers several benefits, including:

- Increased precision and durability of the plastic components.

- Reduced production costs and lead time compared to other manufacturing methods.

- Minimized waste generation and material savings.

- Ability to produce plastic components according to customer requirements and meet different technical specifications.