The mold for the printer equipment Front Frame L193

The mold for printer components plays a crucial role in the production of plastic or metal parts for the printer. These molds are typically made of steel or aluminum and are designed with precise shapes and sizes to create components that meet the required dimensions and shapes for the printer.

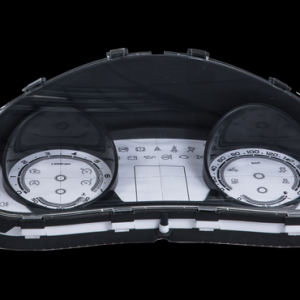

Printer components include mechanical parts such as gears, shafts, springs, ink conduits, paper trays, drive mechanisms, as well as electronic parts like the mainboard, motor controller, sensors, LED lights, and more. The mold for printer components is essential in the manufacturing process of these parts, ensuring their quality and accuracy.

The production process of the mold for printer components involves various steps, from initial design to machining and finishing the casting mold. Subsequently, the mold for printer components will be used in the plastic molding or machining process to create specific components for the printer.

To ensure the accuracy of the components, the mold for printer components must be designed and machined with technical precision, and the production process must adhere to strict quality standards. Without proper design and production processes, the resulting components may have defects or fail to meet the printer’s technical requirements, leading to issues and impacting the performance and reliability of the printer.